Before we get to the good stuff, let's talk about why bike manufacturing has been such an environmental party pooper. Spoiler alert: it's complicated, and yes, aluminium production is basically the elephant in the room that's actually a massive CO2-emitting machine.

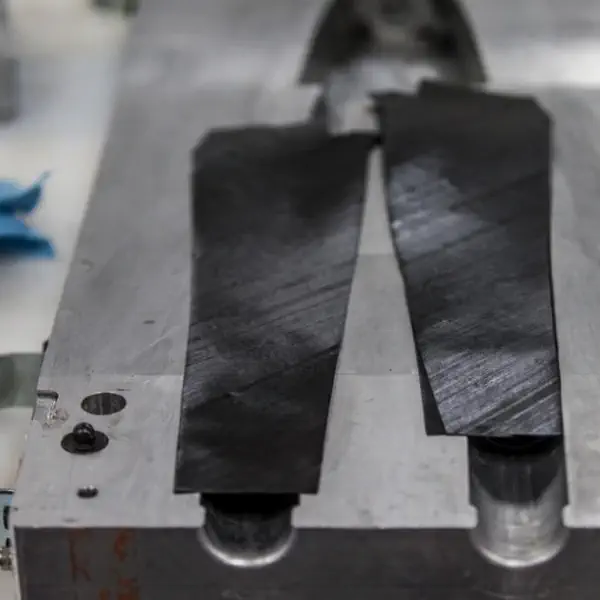

Traditional bike manufacturing is a carbon-intensive affair that starts long before you even unbox your dream ride. Take carbon fiber, for instance – that magical material that makes bikes feel like they're floating uphill while simultaneously making your wallet feel significantly lighter. Producing virgin carbon fiber requires temperatures around 1,500°C and gobbles up more energy than a toddler after a sugar binge.

Then there's aluminium, the OG workhorse of the bike world. While endlessly recyclable (hooray!), primary aluminium production is responsible for about 1% of global greenhouse gas emissions – and that's when the industry is having a good day. The process involves electrolysis that's so energy-intensive, it makes Bitcoin mining look like a meditation retreat.

But wait, there's more! Your bike's journey from factory to garage typically involves shipping components from multiple countries, assembling them in another facility, then shipping the finished product to your local shop. It's like a carbon-heavy world tour that would make even the most jet-setting rock star blush.

And let's not forget the packaging – plastic foam, bubble wrap, and zip ties.